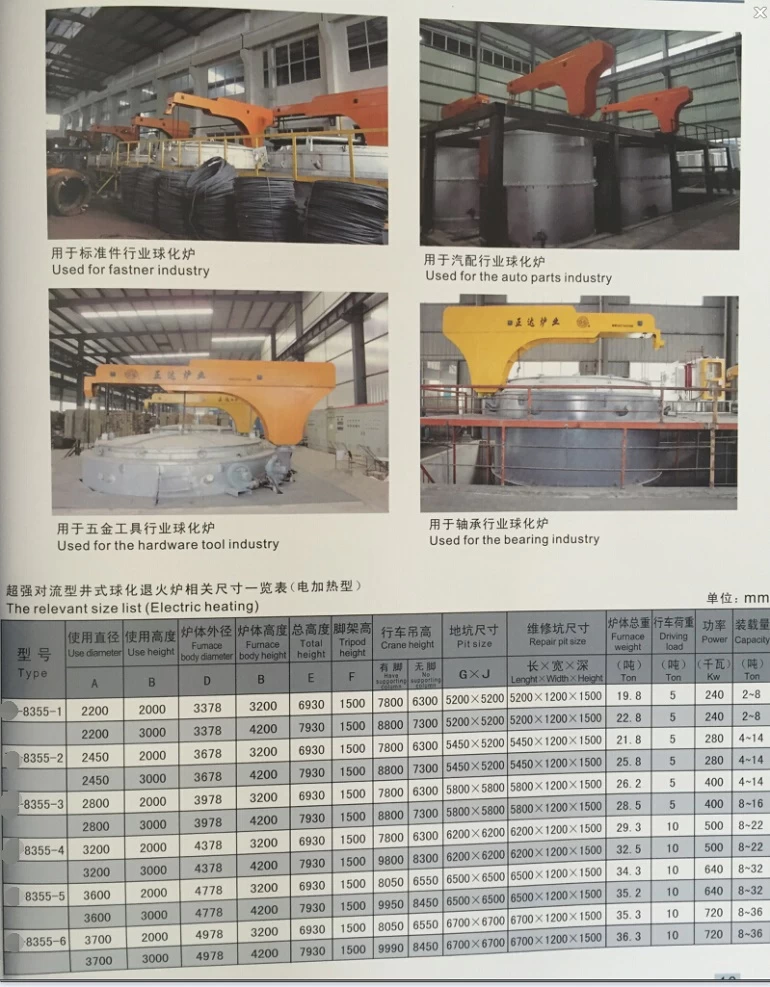

Application: Mainly applied in spheroidizing annealing for wire coil of low-carbon steel, alloy steel, and bearing steel.

It meets the deep processing requirement of the mechanical properties of steel after heatment.

It acquires non-oxidation decarbonization, spheroidizing tissue uniformity and good quality of cold plastic deformation (such as stamping and cold forging).

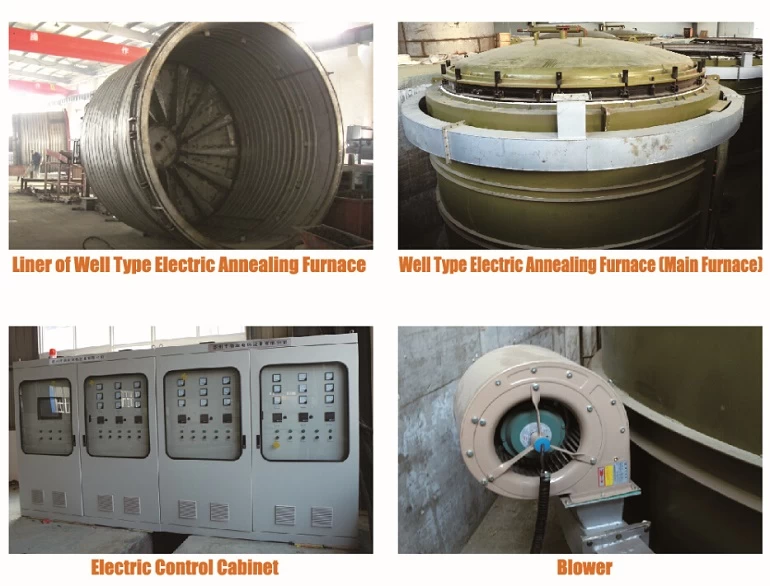

Well type structure can be buried underground, so it occupies small area; it adopts electrical heating and automatic heatment process.

The furnace lining adopts full fibre, heat efficiency and energy conservation highly promoted. The furnace top is equipped with strong convection blower

so the temperature uniformity of whole furnace is good.(+-5℃); adopting protective gas and non-oxidation heatment to reduce metal loss; feeding material is convenient.

Above loadage is for iron wire for your reference. The loadage changes according to Dia, Height and Weight of iron wire.