Automatic product Powerful factory electroplating machine metal New design hot dip galvanizing ma

Hot dip galvanizing introduction

Hot dip galvanizing refers to the method of immersing metal in molten corrosion-resistant metal solution for a short time, taking it out and cooling it to form a covering on the surface of the metal.Galvanized steel plate, steel pipe, steel wire, etc. can prevent atmospheric and water corrosion;Hot plating can prevent oleic acid erosion, and;No toxic salt is produced and is often used in canned foods.Hot coating and metal surface bonding firm, hot plating method simple operation, high productivity, widely used.

Hot dip galvanizing is one of the best coating methods for various protective steel substrates.It is in the liquid state of zinc, after quite complex physical and chemical action, steel is not only coated with a thicker layer of pure zinc, but also a zinc-ferroalloy layer.This plating method not only has the corrosion resistance characteristic of galvanizing, but also has the zinc-ferroalloy layer.It also has a strong corrosion resistance that can not be compared with electric galvanizing.Therefore, this plating method is especially suitable for all kinds of strong acid, alkali fog and other strong corrosion environment.

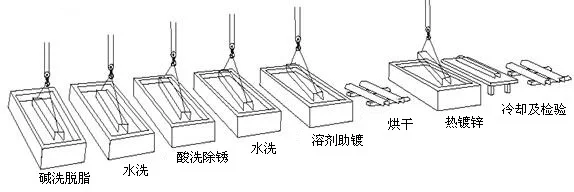

Hot dip galvanizing process

Degreasing → washing → pickling → washing → dipping and plating solvent → drying preheating → hot dip galvanizing → finishing → cooling → (passivation) → rinsing → drying → testing

I