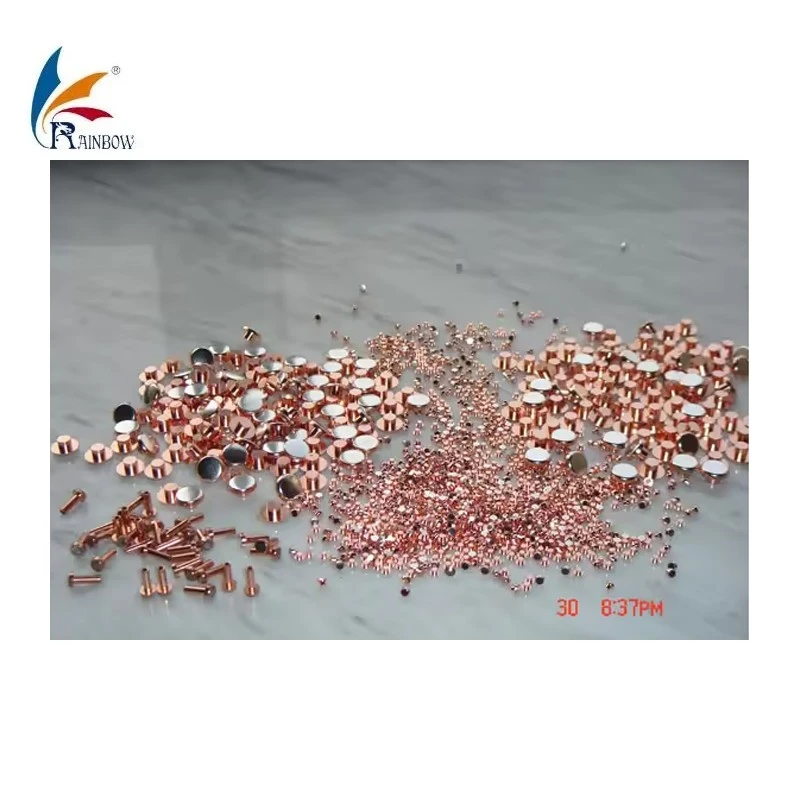

Digital Production Management System Of Bi Metal Machine

Digital Production Management System Of Bi metal rivet making machine

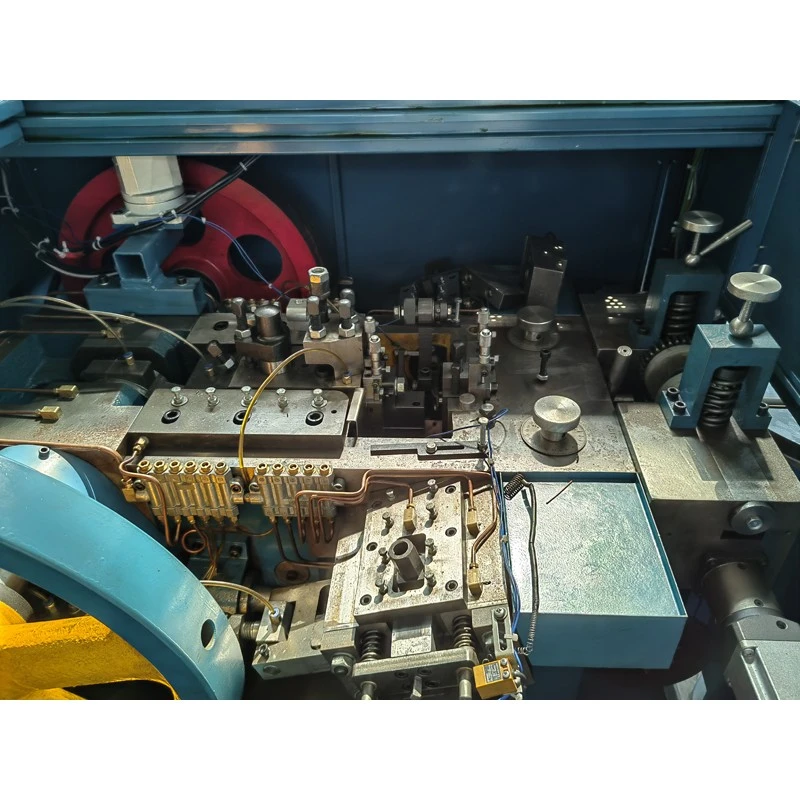

HSD30C、HSD50C Operation and debugging Instructions

1.1 Connect the power supply and inspect each component

Connect the power supply (make sure the grounding wire is connected), check the oil circuit and pneumatic circuit, etc., check if there are any abnormal movements of each component, check whether the reciprocating motion of the cylinder of the non-conforming product separation device of the bucket is in the correct position, ensure that the baffle is in close contact with the inner wall of the bucket, and ensure the air source is unobstructed.

1.2 Feed the wire

After the machine is powered on, a wire is inserted into the hole of the material shortage detection sensor. When the signal indicator light is on, it indicates that the material shortage detection sensor is working and the machine can operate normally. If there is wire material in the detection hole and the indicator light does not light up, turn the sensitivity adjustment screw clockwise to increase the sensitivity. If during the machine's running-in or debugging stage, a small section of copper wire needs to be inserted to keep the signal indicator light on; otherwise, the machine cannot operate.

1.3 Main Interface

1.3.1 Select the Chinese or English mode, click "Adjust the Machine", and enter the adjustment mode . In the adjustment mode, the equipment can only run in point motion and cannot run continuously.

1.3.2 Click "Run", and the machine can run continuously. The jog button does not work.

1.4 Set the parameters for machine adjustment

After the machine is turned on, set the following parameters:

① Pre-set the deviation values for the first and second strokes . The initial value of this value is 10-20. Depending on the quality and size requirements of the contacts, there may be slight changes. Adjust it according to the actual production situation to ensure that the tolerance value is within the size requirements of the contacts.

② Set the pre-order quantity for normal operation . When the machine is running normally, the first few items are regarded as non-conforming products and separated into the non-conforming product material pipe. It can also be set to zero.

③ Set the production output ;

④ Number of mold repair and fitting reminders;

⑤ Set the oil supply time and interval time of the oil pump;

⑥ Output is reset to zero .

1.5 Check the order information

Check the production order interface and select the wire material and mold