Tightening bolts can not be ignored friction can cause problems to solve the problem

2016-06-02 10:59:54

fortensionbolt, The friction force is a factor to be reckoned with. Bolt friction joint has been in existence, it may be part of the reason that caused the problem, it can also be used to solve the problem.

Friction is a force that occurs when two objects in contact with each other. It is opposed to all capacity. No matter which direction the object moves, the friction drag all the objects in the other direction.

However, we need to friction. No friction, we can not walk, can not sit on a chair or climbing stairs. Everything just kept sliding around.

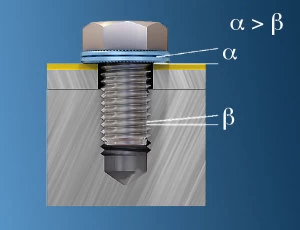

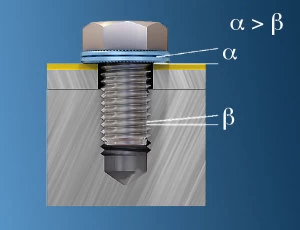

FRANK NAUMANN is a former managing director of the German Association of fasteners, has 50 years of professional experience in the field of friction, he explained friction in bolt connection is always the presence of the phenomenon. On the one hand, it limits the torque is converted to the desired preload efficiency; on the other hand, to maintain joint preload to prevent loose parts, it is essential to it. Naumann said: "There are two factors described friction during tightening rotating member is between the first bearing surface friction coefficient under the screw head or nut between μb (μb = washer friction); section. is the coefficient of friction between the two threads of μth (μth = thread friction). both friction will consume a lot of energy, and the energy into unwanted heat. for example, if μb = μth = 0.10, only 16% of the torque converted into preload. and people can be controlled to affect the size of lubrication factor in the automotive industry, used mostly in the range of 0.08 to 0.16 between. "

Naumann said: "There are two factors described friction during tightening rotating member is between the first bearing surface friction coefficient under the screw head or nut between μb (μb = washer friction); section. is the coefficient of friction between the two threads of μth (μth = thread friction). both friction will consume a lot of energy, and the energy into unwanted heat. for example, if μb = μth = 0.10, only 16% of the torque converted into preload. and people can be controlled to affect the size of lubrication factor in the automotive industry, used mostly in the range of 0.08 to 0.16 between. "

inBoltedAspect, the friction can sometimes be used to solve the problem, it may be part of the reason causing the problem. Of course, the main bolt clamping force is determined by the torque required to tighten bolts, but also by many other effects, such as the diameter and length of the threaded bolt shape, of course, we can not forget that there are in the thread andBolt head and nutFriction coefficient under.

In the calculation of the bolt tightening torque and the resulting stress and tension, and a connecting surface between the calculated frictional force generated by the friction coefficient it is necessary.

However, the approximate value of the coefficient of friction as shown in the chart are only representative values, should control other sources of information and the appropriate tests be confirmed.

Torque value depends on the frictional force present in the thread and tightened the bolt head and nut with fastening material or washer (if used). In fact, in the tightening process, almost all the input energy is lost in overcoming friction head bolt, nut and screw on the under. Only a small part of the torque is converted to the clamping force or tension loads.

Torque wrench can not directly measure the bolt preload. When applying torque must overcome bolt head and nut (depending on which side is twisted), the screw and the static friction.

Most of the applied torque (about 50%) will be applied to overcome the loss in friction torque under the bolt head and nut, and about 40% of the torque to overcome losses in the thread friction torque remaining 10% effective role in tensile bolts and providing preload.

Increase the friction common method is to avoid the bolts loose, the most common examples include the use of deformed threads, or nylon locknut, or zig-zag / tooth / star washers. These solutions, the principle is to increase the friction friction locking threaded nut or bolt head and under.

However, as torque, seizure and wear of metals such factors, which have a negative impact on friction solutions.

The locking method based on friction, increasing joint torsional stress can also cause problems. High torque may cause the fastener below the estimated damage grievance under preload. And because non-uniform friction conditions, may be unable to achieve the required preload.

Fasteners made of stainless steel, aluminum, titanium, and other alloys, the same unpredictable thread galling (cold welding) may occur. When tightening bolts, since the contact surface pressure and the sliding surface of the threads increases, so the thread may be worn during tightening of the fastener.

In extreme cases, it can cause metal wear seizure, that is, thread and bolt lock, and secured together. Continue tightening may cause or threaded fasteners wring tears.

Lubricants reduce friction, and are typically used to obtain a uniform clamping force load. Lubrication and external threads can often eliminate thread wear.

Dörken product manager Michael Stähler, said the trend is currently applying a suitable coating on the bolt or nut, the coating is designed to perform the intended work and design. In fact, this coating containing lubricating oil; no longer have separate lubricated coating is applied, because it is unnecessary. In addition, this coating temperature instability can lead to self-loosening of the joint.

However, the lubricant will significantly weaken or even eliminate any friction locking locking performance-based approach. Therefore, the lubricating oil must not be used in combination with friction locking method based lubricants can weaken because the locking performance.

Clamp load control is very important, it can be achieved by reducing the coefficient of friction instability. When bolted joint solutions, if not based on friction force locking, you can use lubricants.

By lubricants reduce friction, we can improve the preload control and reduce the friction coefficient of instability. This way you can make the bolt reaches full load and extend the life of the bolted joint. Bolt failure due to fatigue caused by wear and tear can cause annoying production downtime.

Friction is a force that occurs when two objects in contact with each other. It is opposed to all capacity. No matter which direction the object moves, the friction drag all the objects in the other direction.

However, we need to friction. No friction, we can not walk, can not sit on a chair or climbing stairs. Everything just kept sliding around.

FRANK NAUMANN is a former managing director of the German Association of fasteners, has 50 years of professional experience in the field of friction, he explained friction in bolt connection is always the presence of the phenomenon. On the one hand, it limits the torque is converted to the desired preload efficiency; on the other hand, to maintain joint preload to prevent loose parts, it is essential to it.

Naumann said: "There are two factors described friction during tightening rotating member is between the first bearing surface friction coefficient under the screw head or nut between μb (μb = washer friction); section. is the coefficient of friction between the two threads of μth (μth = thread friction). both friction will consume a lot of energy, and the energy into unwanted heat. for example, if μb = μth = 0.10, only 16% of the torque converted into preload. and people can be controlled to affect the size of lubrication factor in the automotive industry, used mostly in the range of 0.08 to 0.16 between. "

Naumann said: "There are two factors described friction during tightening rotating member is between the first bearing surface friction coefficient under the screw head or nut between μb (μb = washer friction); section. is the coefficient of friction between the two threads of μth (μth = thread friction). both friction will consume a lot of energy, and the energy into unwanted heat. for example, if μb = μth = 0.10, only 16% of the torque converted into preload. and people can be controlled to affect the size of lubrication factor in the automotive industry, used mostly in the range of 0.08 to 0.16 between. "

inBoltedAspect, the friction can sometimes be used to solve the problem, it may be part of the reason causing the problem. Of course, the main bolt clamping force is determined by the torque required to tighten bolts, but also by many other effects, such as the diameter and length of the threaded bolt shape, of course, we can not forget that there are in the thread andBolt head and nutFriction coefficient under.

In the calculation of the bolt tightening torque and the resulting stress and tension, and a connecting surface between the calculated frictional force generated by the friction coefficient it is necessary.

However, the approximate value of the coefficient of friction as shown in the chart are only representative values, should control other sources of information and the appropriate tests be confirmed.

Torque value depends on the frictional force present in the thread and tightened the bolt head and nut with fastening material or washer (if used). In fact, in the tightening process, almost all the input energy is lost in overcoming friction head bolt, nut and screw on the under. Only a small part of the torque is converted to the clamping force or tension loads.

Torque wrench can not directly measure the bolt preload. When applying torque must overcome bolt head and nut (depending on which side is twisted), the screw and the static friction.

Most of the applied torque (about 50%) will be applied to overcome the loss in friction torque under the bolt head and nut, and about 40% of the torque to overcome losses in the thread friction torque remaining 10% effective role in tensile bolts and providing preload.

Increase the friction common method is to avoid the bolts loose, the most common examples include the use of deformed threads, or nylon locknut, or zig-zag / tooth / star washers. These solutions, the principle is to increase the friction friction locking threaded nut or bolt head and under.

However, as torque, seizure and wear of metals such factors, which have a negative impact on friction solutions.

The locking method based on friction, increasing joint torsional stress can also cause problems. High torque may cause the fastener below the estimated damage grievance under preload. And because non-uniform friction conditions, may be unable to achieve the required preload.

Fasteners made of stainless steel, aluminum, titanium, and other alloys, the same unpredictable thread galling (cold welding) may occur. When tightening bolts, since the contact surface pressure and the sliding surface of the threads increases, so the thread may be worn during tightening of the fastener.

In extreme cases, it can cause metal wear seizure, that is, thread and bolt lock, and secured together. Continue tightening may cause or threaded fasteners wring tears.

Lubricants reduce friction, and are typically used to obtain a uniform clamping force load. Lubrication and external threads can often eliminate thread wear.

Dörken product manager Michael Stähler, said the trend is currently applying a suitable coating on the bolt or nut, the coating is designed to perform the intended work and design. In fact, this coating containing lubricating oil; no longer have separate lubricated coating is applied, because it is unnecessary. In addition, this coating temperature instability can lead to self-loosening of the joint.

However, the lubricant will significantly weaken or even eliminate any friction locking locking performance-based approach. Therefore, the lubricating oil must not be used in combination with friction locking method based lubricants can weaken because the locking performance.

Clamp load control is very important, it can be achieved by reducing the coefficient of friction instability. When bolted joint solutions, if not based on friction force locking, you can use lubricants.

By lubricants reduce friction, we can improve the preload control and reduce the friction coefficient of instability. This way you can make the bolt reaches full load and extend the life of the bolted joint. Bolt failure due to fatigue caused by wear and tear can cause annoying production downtime.

NORD-LOCK friction for innovative solutions

NORD-LOCK washers with tension instead of friction to tighten bolted joints. This gasket is designed to produce a wedging effect, when we loosen the bolt tension increases observed, in order to confirm this effect.

This wedging effect can avoid loose threads or vibration caused by the impact. Due to unusual settlement between the contact surface, only at the beginning of the loss of bolt pretension small portions.

Security locking bolt threads while reducing friction is often thought to be impossible. However, with the Nord-Lock wedge locking method based on tension and lubricants help make the impossible possible.

Nord-Lock Application Engineer Lena Kalmykova said: "The wedge locking method is based on the most common tension instead of friction wedge locking system is a pair of cam washer, the cam ridge portion than the height of the bolt. pitch is also great. the method of installation of the washer is mounted opposite the cam surface and the cam surface. when the bolt / nut is tightened, the teeth engaging and locking engagement face, only to allow any rotational movement of the cam surface of the bolt / nut It was blocked by the wedge effect of the cam. wedge locking capability without lubricant in. in addition, by using such a washer, you can realize the full performance of each bolt. "

NORD-LOCK washers with tension instead of friction to tighten bolted joints. This gasket is designed to produce a wedging effect, when we loosen the bolt tension increases observed, in order to confirm this effect.

This wedging effect can avoid loose threads or vibration caused by the impact. Due to unusual settlement between the contact surface, only at the beginning of the loss of bolt pretension small portions.

Security locking bolt threads while reducing friction is often thought to be impossible. However, with the Nord-Lock wedge locking method based on tension and lubricants help make the impossible possible.

Nord-Lock Application Engineer Lena Kalmykova said: "The wedge locking method is based on the most common tension instead of friction wedge locking system is a pair of cam washer, the cam ridge portion than the height of the bolt. pitch is also great. the method of installation of the washer is mounted opposite the cam surface and the cam surface. when the bolt / nut is tightened, the teeth engaging and locking engagement face, only to allow any rotational movement of the cam surface of the bolt / nut It was blocked by the wedge effect of the cam. wedge locking capability without lubricant in. in addition, by using such a washer, you can realize the full performance of each bolt. "

Facts about friction

Friction depends on the surface characteristics - flat, round or rough level. Friction is also dependent on the surface in which the media - is wet or dry, medium or particles.

It is a multidisciplinary field, because it relates to mechanical, chemical and other fields such as fluid dynamics. Only the atomic level, you can have full friction, detailed understanding.

Classic sliding friction of the rules was first discovered by Leonardo da Vinci, then by Guillaume Ammon East (Guillaume Amontons) rediscovered. Amon east from surface unevenness, and lift the lamination surface of the power of desired weight paper proposes the nature of friction.

The last century, at the micro level have shown that the actual contact area is only apparent contact area is a small part. Development of an atomic force microscope has enabled scientists to study friction at the atomic scale.

Friction depends on the surface characteristics - flat, round or rough level. Friction is also dependent on the surface in which the media - is wet or dry, medium or particles.

It is a multidisciplinary field, because it relates to mechanical, chemical and other fields such as fluid dynamics. Only the atomic level, you can have full friction, detailed understanding.

Classic sliding friction of the rules was first discovered by Leonardo da Vinci, then by Guillaume Ammon East (Guillaume Amontons) rediscovered. Amon east from surface unevenness, and lift the lamination surface of the power of desired weight paper proposes the nature of friction.

The last century, at the micro level have shown that the actual contact area is only apparent contact area is a small part. Development of an atomic force microscope has enabled scientists to study friction at the atomic scale.

This article is reproduced: Ekintong