Automatic tapping machine fully explained!

First, the working principle of automatic tapping machine

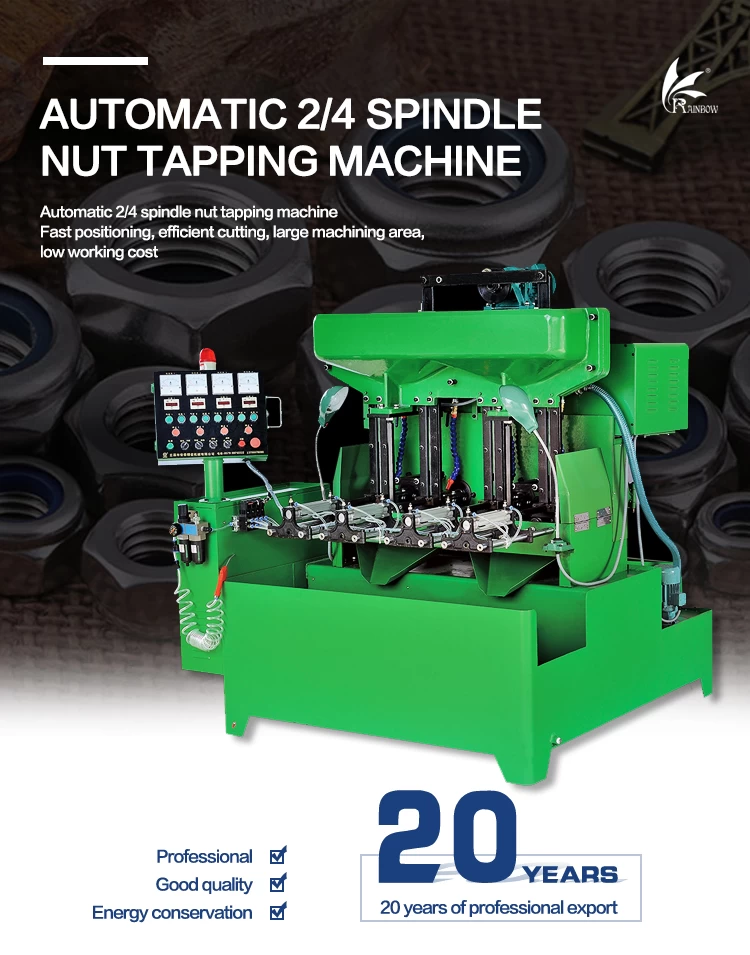

Automatic tapping machine has a high degree of automation, when working, as long as the parts blank into the hopper can be automatically feeding, automatic positioning, automatic clamping, automatic tapping, automatic unloading, a worker can operate multiple equipment at the same time, high production efficiency, can significantly save labor costs! High-quality tapping machine has the characteristics of novel design, reasonable structure, simple and easy to use, high degree of automation, easy to use, high efficiency, maintenance-free, extremely cost-effective, etc., high-quality nut tapping drilling machine processing of various nut thread finish is high, finished product qualification rate is high.

Second, what are the performance advantages of automatic tapping machine

1. The automatic tapping machine is to liberate manpower, and there is no need to rely on manpower to tap the thread like a manual tapping machine. The automatic tapping machine can also add multi-axis to complete several or even a dozen teeth at once. High precision, fast efficiency, shorten the product processing cycle and ensure quality.

2. Tapping depth setting

Before tapping, according to the depth requirements of the tapping, enter the corresponding data on the control interface, the tapping machine automatically taps to the set depth according to the input control data, and automatically exits, which can be assured to boldly tap the blind hole thread, greatly reducing the labor intensity and the technical requirements of the operator.

3. Tapping speed setting

The speed setting of the servo synchronous tapping power head adopts the DC quasi-voltage input setting, which can realize stepless speed regulation of the spindle and feed (within the maximum speed range)

4. Universal adjustment setting

The servo synchronous tapping power head can be tapped in any position and is light to operate.

5. Safety chuck torque setting

The tapping chuck has an overload protection function, so that the tap is not easy to break.

6. Servo motor overload protection

The motor automatically alarms to stop working under overload and overcurrent to avoid damage to the motor due to overcurrent and overload.

7. The pitch size can be changed at will

The servo synchronous tapping power head can process any metric thread, and the changing pinion can also machine any pitch specification.

8. It can be equipped with multi-axis tapping head to improve production efficiency

A servo synchronous tapping power head plus a biaxial or multi-axis tapping head enables threads with multiple bore diameters to be machined at once. The greatly improved production efficiency is several times that of ordinary tapping power heads.

Third, what is the positioning of the automatic tapping machine?

The positioning device of the tapping machine, that is, the device that fixes the workpiece on the equipment by restricting the degree of freedom of the workpiece during the working process of the tapping machine to ensure the accuracy of tapping positioning. The effect of positioning and the convenience of positioning have a great impact on the tapping accuracy and tapping efficiency of the tapping machine, and also have an indirect impact on the development of industry.

4. What problems should be paid attention to when using automatic tapping machine?

1. Check the power supply voltage single-phase 220VAC, the shell is well grounded, the power supply connection is correct, and the power is used safely.

2. Determine an installation platform, stable table and large stretching space to ensure that the tapping machine can stretch safely and freely.

3. The bolts of each component are precise and the frame runs flexibly.

4. Check the size of the thread bottom hole and choose the suitable tap.

5. The working speed of tapping is determined according to the size of the tap and the product material, please set the working speed correctly according to the size of the tap and the product material in use.

6. When using and replacing the tap, adjust the high and low gears and speed according to the size of the tap to prevent the tap from being damaged due to too high speed and reducing the working efficiency due to too low speed.

7. Correct use of tapping oil, the quality of tapping oil directly affects the tapping effect, to ensure smooth tapping lubrication.

8. Check the sharpness of the tap intermittently during tapping. If you encounter missing teeth or sticky chips and poor chip evacuation, you should check and replace the tap or tapping oil according to the situation.

9. Pay attention to the tapping sound during tapping, and stop and check in time if there is an abnormal sound.

10. The tapped workpiece is installed firmly and reliably.

11. If the tap stops due to poor chip removal, use the exit button in time to run the front and reverse.

12. Keep all parts of the equipment tidy. The drive control panel reversing button, wires, plugs are neat and clean.

13. The tap chuck has overload protection function, and the adjustable safety clutch is separated when the tapping exceeds the rated pressing moment to avoid damage to the tap.

In fact, about the above points is not enough to say all the performance characteristics of the automatic tapping machine, because the technology is constantly innovating, the equipment is more and more automated and intelligent day by day, the only sure point is that the traditional tapping machine will be slowly eliminated and launched into the historical stage, that is to say, if your factory is no longer on the automation equipment will also be surpassed by competitors or even eliminated, Domi Machinery professional research and development and manufacturing of automatic drilling and tapping equipment, brand quality after-sales perfect, welcome to consult!