Considerations for Selecting the Proper Fastener (2)

3. What size fastener is needed?

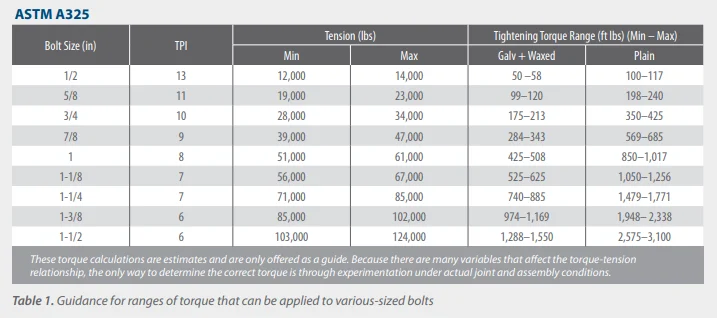

The fastener needs to clamp parts together; and the clamping force must be sufficient to prevent separation of movement between the clamped parts when forces are applied. Selecting the correct fastener diameter to support the required clamp force will provide a secure, high reliability joint. A common problem is the selection of an under-sized fastener and using a higher strength material. The designer will specify a high torque for the fastener. The high torque causes the fastener to stretch by an excessive amount. Similarly, selecting an over-sized fastener does not necessarily lead to a tighter clamped joint. An over-sized fastener will stretch less under tension and result in the possibility of bolt loosening. Table 1 offers guidance on bolt size and ranges of tightening torque for uncoated bolts and galvanized and waxed bolts. Selecting the properly sized fastener and specifying an appropriate torque are challenges. Inexperienced designers should consider consulting with an expert.

4. Does the application require a screw or a bolt?

Often the terms, screw and bolt, are used interchangeably. There are differences between when these two fasteners types are used. Bolts are used when joining two or members together with a mating nut. Screws are used in applications where the one of the mating members has an internally tapped thread. Bolts are more appropriate if the forces on the joint vary during use. Also, if the joint is subject to temperature changes or vibration, a bolt with a nut would be more capable of keeping the joint securely clamped. In high vibration environments, a locking feature, such a lock nut, lock washer, prevailing torque patch, or thread adhesive is recommended. For joints in which the forces on it are relatively constant, low, and the joint is not subject to temperature swings, a screw can be a sufficient clamping solution. However, material selection, heat-treat, and other design considerations allow screws to be used with joints that have dynamic and cyclical loading. An example of such a screw would be a “head bolt” for an internal combustible engine. In many applications, the selection of a screw or bolt is already dictated by the various mating members of the joint.