Considerations for Selecting the Proper Fastener (3)

5. How long should the fastener be?

The fastener needs to be long enough to completely engage the mating parts that need to be clamped together. Use of a long fastener does not compromise the joint as long as it secures the assembly together completely. If a designer selects a bolt, the bolt must be long enough to hold the assembly that needs clamping, any required gaskets or washers, and a nut. In addition, the bolt length should extend beyond the depth of the joint to allow for some excess threads. The extra length ensures that the nut is fully installed on the bolt. Also be aware of fastener dimension conventions. The length of a fastener is a function of the style of its head and how much of the fastener fits in the joint. If the head of the fastener mounts on the surface of the joint, then the fastener length only includes the dimension of the threaded portion of the fastener. For fasteners with heads that fit into the joint, the length includes the dimensions of the head and the dimension of the threaded portion. See Figure 1.

The thread diameter is the outer diameter of the threaded section of the fastener. It is the major diameter and is typically referred to as the diameter of the fastener. On the majority of fasteners, the shank or body diameter is roughly the same as the thread diameter. Again, defining the wrong dimension can cause an unstable connection between the materials that must be held together.

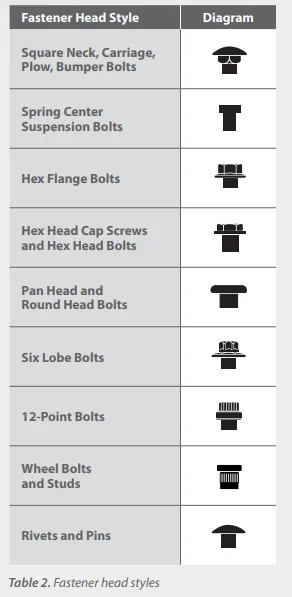

6. What type of fastener head should be used?

A fastener can have a screw head, socket head, a hex head, or another style head. The design of the fastener head is important for supporting the amount of torque the fastener must withstand. If a joint is in an area with restricted access, the head may require a custom design to allow a tool to assemble and tighten the fastener. The need for a special fastener head should not deter the designer; many manufacturers can accommodate custom designs. Proper selection of the head will facilitate the assembly and tightening of the fastener to the appropriate torque. Table 2 shows a wide range of head styles, primarily for bolts.