How to improve the anti-fatigue bolt?

Q: How can I improve resistance to fatigue?

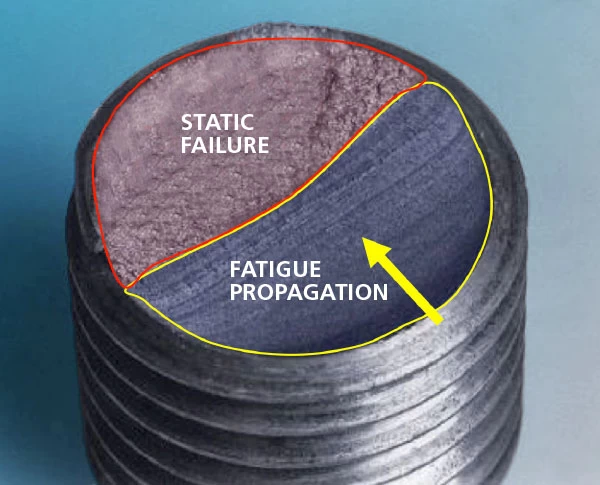

A: resistance to fatigue bolted much smaller than its static affordability. To improve the fatigue resistance, designers can increase the thread strength, lower alternating stress threads.

To improve the strength of the thread, we recommend rolling, rather than cutting process. To increase the strength of the bolt connection, a plurality of smaller fasteners are available, rather than a single large fasteners.

In addition, through an improved connector, for example, Superbolt more pushing pretensioner or Flexnut (elastically stretchable nut). They can improve the thread load distribution, increases the elasticity of the bolt connection, thereby enhancing the strength of the bolt connection.

To improve the fatigue resistance, the best way is to reduce the thread withstand alternating stress, but there are three main ways: component design, assembly fastening component protection.

In the process of design components, we have the opportunity to improve load distribution bolted, reducing the stress of each joint bear. To do this, keep in mind the following principles:

1.? Use the largest preload

2.? Bolt to minimize the load eccentricity

3.? Use the largest possible contact surface

4.? Whenever possible, use the maximum clamping length

5.? In most cases, the workload should be higher than preload

Design component, may also be used necking or studbolt,as well asSpring washerTo offset the loose, differential thermal creep and tensile impact.

To tighten the terms of components, to achieve the necessary preload is to reduce the alternating pressure of the main factors. We recommend the use of high-precision calibration tool and the appropriate lubricants, preload ensure accuracy, reducing the risk of seizure. Tightening sequence properly, can reduce the risk of uneven load of bolts, ensure that the entireboltConnection integrity.

As component protection, consideration should be given to prevent the bolt preload connection loss, but also to avoid the components from environmental influences, such as may be induced corrosion fatigue cracking. To do this, select the appropriate material and / or coating of parts and fasteners.