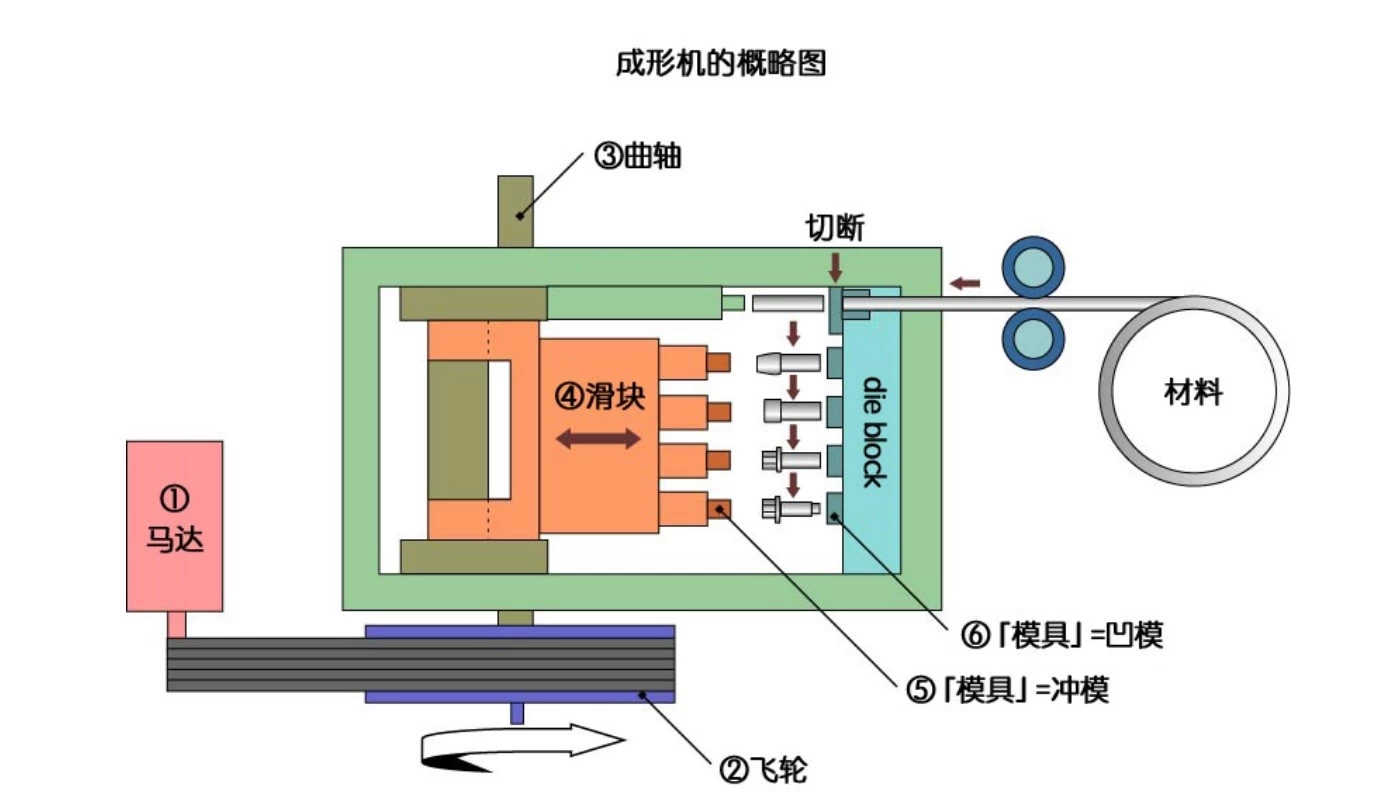

Schematic Diagram of a Cold Forging Machine

About Cold Forging

Cold forging is a method of metal forming processing that occurs at room temperature or slightly elevated temperatures, unlike traditional hot forging, which requires heating metals to high temperatures.

The cold forging process typically involves placing metal materials in a specifically shaped mold and then applying high pressure to shape and deform the metal to fit the mold's shape. This process can be performed using a press or a stamping machine to ensure high control and precision. Cold forging is often used to manufacture high-precision parts and components that require very high standards for shape, size, and surface quality.

Compared to hot forging, cold forging has several advantages:

1. Energy-saving and environmentally friendly: Since it does not require additional heating energy, cold forging consumes less energy, thereby reducing carbon emissions and energy waste.

2. Increased material strength: Cold forging can increase the strength and hardness of materials due to the phenomenon of strain hardening that occurs during processing at room temperature.

3. Less subsequent processing: Because cold forging can manufacture parts with higher precision and surface quality, it typically requires fewer post-processing and finishing steps

4. Reduced material waste: Cold forging has a higher material utilization rate, as very little material is cut or removed during the process.

Cold forging is widely used in industries such as automotive, aerospace, electronics, and machinery, especially in the production of large quantities of high-quality small metal parts and fasteners. It plays an important role in engineering manufacturing, providing efficient, energy-saving, and high-quality solutions for the production of various products.

Schematic diagram of a cold forging machine