Thread rolling machine working principle-Screw making machine--Harbin Rainbow Technology

Thread rolling machine(Harbin Rainbow Technology) is specialized in the production of screws. The machine is light, flexible and efficient. The machine avoids the limitations of lathes, drilling machines or manual tapping. It saves time and effort, and is not easy to rot teeth and tap is not easy to break. Silk rolling machine is suitable for all machinery production industries, machine tools, molds, plastic machinery, printing machinery, packaging machinery manufacturers, engineering machinery, hook car motorcycle parts, aviation motor, rolling stock, tobacco machinery and general machinery and other industries.

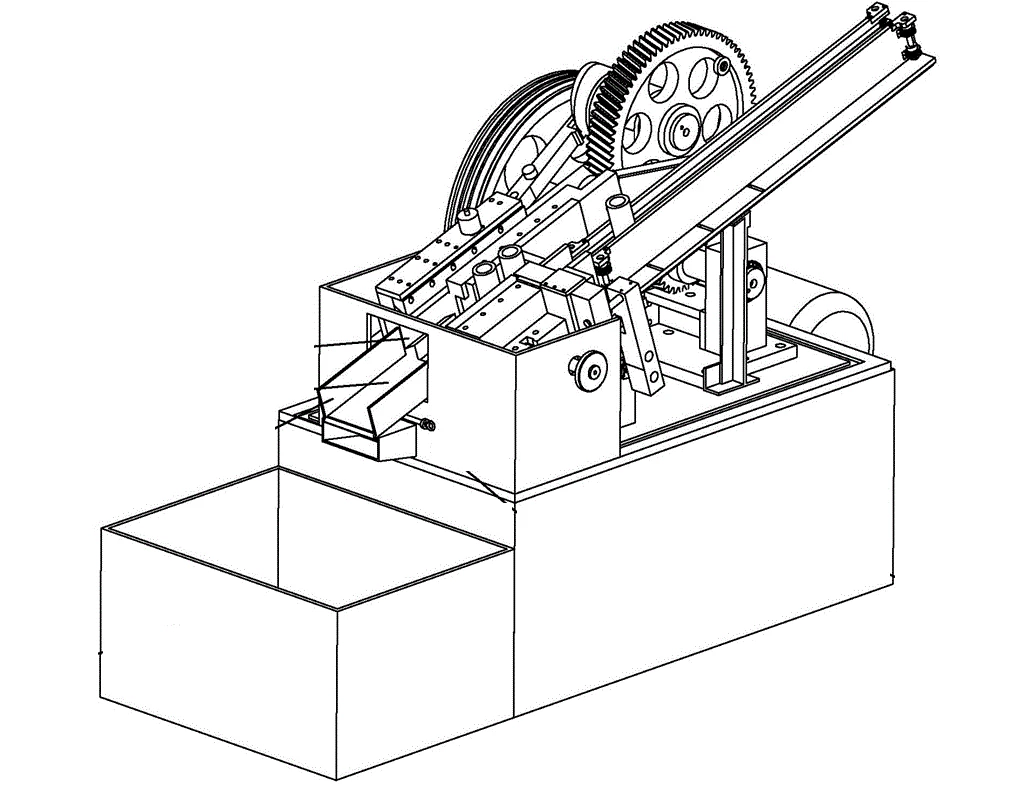

The thread rolling machine(Harbin Rainbow Technology) is composed of a transmission part, a bend arm part, and a working part, including a frame, a running track, a dynamic thread rolling plate, a fixed thread rolling plate, a guide slide, etc. Its working principle is through the rotation of the bending arm, driving the thread rolling plate to do reciprocating motion, and the constant rolling plate interaction extrusion workpiece, to achieve the purpose of processing.

Threading principle (Harbin Rainbow Technology)is the use of metal plasticity, the formed semi-finished products to press, in order to achieve the required thread specifications, which is characterized by no waste, low cost, high efficiency, high finish, uniform precision, for cutting workers, high output strength. Basic working conditions: two parallel threading plates, with the length of the static plate Ls as the standard, the length is more than 20 times the length of the processed, but not more than 35 times, the number of rotation of processed items in the plate during the superpressing process: Wood screws can not be less than 6 circles, machine screws can not be less than 4 circles, if the number of rotation circles is insufficient, the processed material is subjected to pressure caused by the elliptic or different shape changes, affecting the nature of materials and machinery.

Rules for safe operation of thread rolling machines(Harbin Rainbow Technology)

1 Before starting the machine, carefully check whether the components are normal. Whether the two plates are parallel.

2 All the protective covers on the thread rolling machine should be in good condition and can not be disassembled arbitrarily.

3. During operation, the workpiece and the thread plate shall not be touched by hand. Do not adjust when the machine is started.

4. Before stopping the machine, the blank supply should be stopped first. When there is no blank between the two plates, the power supply can be cut off.

5. If the machine is stopped due to temporary power failure and there is wire between the thread rolling plates, it shall be removed in accordance with the prescribed method and shall not be forced to start.