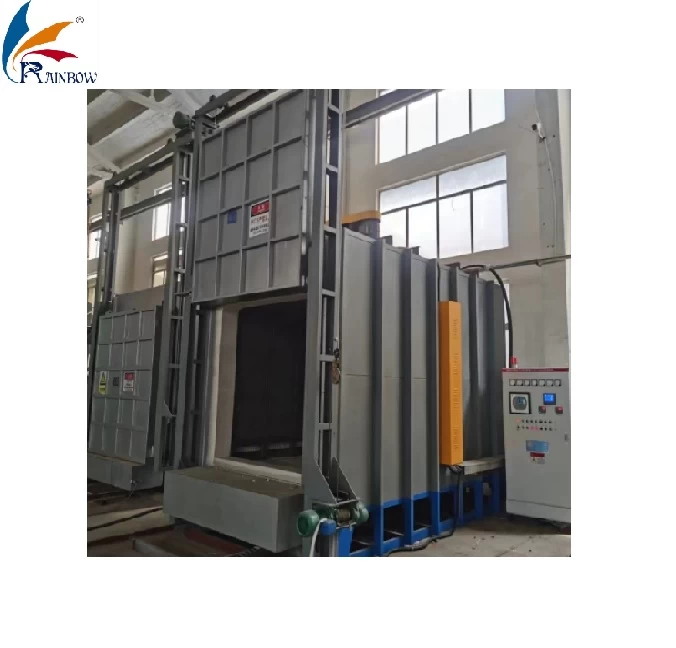

Working principle of trolley annealing furnace

Zoe Jia

2023-06-02 09:45:45

Trolley annealing furnace furnace body left, right, bottom heating, divided into front, middle and back three zones of temperature control, the temperature controller of the electric control cabinet automatically displays the process temperature, the furnace mouth is sealed by high temperature rubber ring, and equipped with water flow device, furnace charging basket and feeding device, mainly used for bright heat treatment of straight metal materials such as copper tubes and steel pipes.

Because Chin, Chin, etc. belong to the WB group of metals, they are active at high temperatures, susceptible to contamination by refractory materials in contact with them, and are more likely to combine with carbon, oxygen, nitrogen and hydrogen. These substances can diffuse through the porous oxide film to form a high-hardness, high-brittleness oxygen-containing pollution layer, which can promote surface cracks and extend into the matrix during use, causing damage. Therefore, the heating and annealing process of the material must be carried out in a vacuum environment.

Trolley annealing furnace principle:

The bottom of the furnace is a movable trolley, before heating, the car is installed in the furnace, heated on a specific cushion iron, and then the car is charged by the traction mechanism inside the heating, and then the car is pulled out of the furnace from the external traction mechanism and then unloaded, or the heated workpiece is processed with forging crane equipment.

When the trolley annealing furnace is working, the thermocouple converts the furnace temperature into a voltage signal and enters the microcomputer temperature control regulator. The regulator compares this signal to the program settings and outputs an adjustable signal. Then the trigger is controlled by the adjustable signal, and the voltage regulator is triggered by the trigger to achieve the purpose of adjusting the voltage and temperature in the furnace.

The specific working process is as follows: the charge enters the cooling chamber from the trolley annealing furnace table for evacuation, and after reaching a defined degree of vacuum, it enters the heating chamber through the cooling chamber, and returns to the cooling chamber After the annealing treatment of the charge is completed, it passes the heating and insulation process, and is sent to the feeding table to cool and complete a working cycle

Because Chin, Chin, etc. belong to the WB group of metals, they are active at high temperatures, susceptible to contamination by refractory materials in contact with them, and are more likely to combine with carbon, oxygen, nitrogen and hydrogen. These substances can diffuse through the porous oxide film to form a high-hardness, high-brittleness oxygen-containing pollution layer, which can promote surface cracks and extend into the matrix during use, causing damage. Therefore, the heating and annealing process of the material must be carried out in a vacuum environment.

Trolley annealing furnace principle:

The bottom of the furnace is a movable trolley, before heating, the car is installed in the furnace, heated on a specific cushion iron, and then the car is charged by the traction mechanism inside the heating, and then the car is pulled out of the furnace from the external traction mechanism and then unloaded, or the heated workpiece is processed with forging crane equipment.

When the trolley annealing furnace is working, the thermocouple converts the furnace temperature into a voltage signal and enters the microcomputer temperature control regulator. The regulator compares this signal to the program settings and outputs an adjustable signal. Then the trigger is controlled by the adjustable signal, and the voltage regulator is triggered by the trigger to achieve the purpose of adjusting the voltage and temperature in the furnace.

The specific working process is as follows: the charge enters the cooling chamber from the trolley annealing furnace table for evacuation, and after reaching a defined degree of vacuum, it enters the heating chamber through the cooling chamber, and returns to the cooling chamber After the annealing treatment of the charge is completed, it passes the heating and insulation process, and is sent to the feeding table to cool and complete a working cycle