What is Cold Heading?

What exactly is Cold Heading? Let’s begin by defining the general term along with the basic principles of involved in the cold heading process.

Cold Head·ing

/kōld/ /‘hediNG/

verb

-

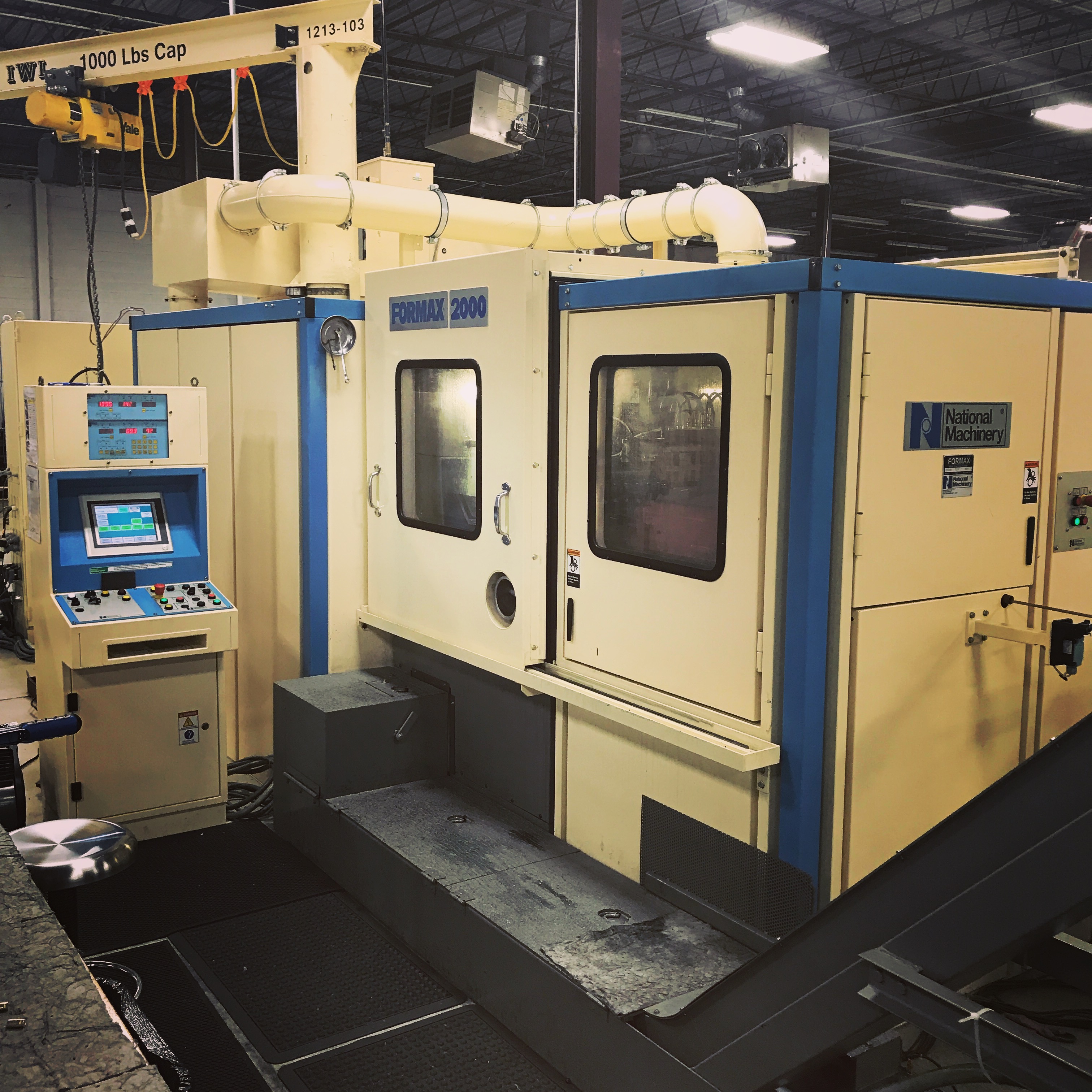

The process of progressively forming a specified shape from metal wire without adding heat – using a replicated series of dies, hammers, and punches at high speed.

Simply put: cold heading is feeding wire into a machine, cutting it into pieces, and hammering on it. The material is not heated or machined, but formed into its desired shape at room temperature. The ability to form material instead of removing it deems this process extremely efficient and cost effective when manufacturing large quantities.

At Grandeur Fasteners, we design and fabricate our own custom tooling and manufacture nearly all fastener forms including multiple upset configurations, customized head shapes, and substitutions for multi-part assemblies. Converting your supply needs to cold heading can benefit in many ways.

-

Tight Tolerances

-

High Speed Production Rates

-

Large Volume Capabilities

-

Reduced Raw Material Waste

-

Improved Physical Properties

-

Reduction in Cost Vs Machining

-

Capabilities Include a Large Range of Diameters

-

Standard and non-standard configurations are made to the customer’s specifications

-

Many secondary operations available to complete fully customized parts

Cold Heading Basics

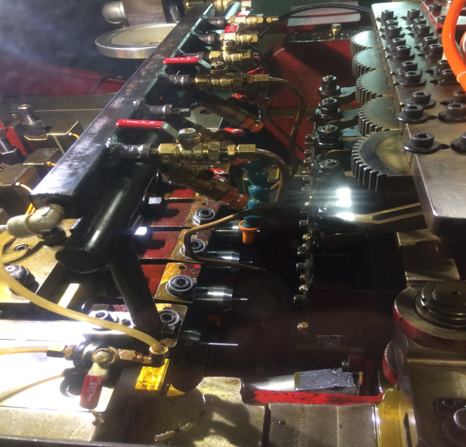

Cold heading (or cold forming) is a method of forming metal in progressive steps into net shaped or near net shaped parts. Starting with a slug, which is cut from a continuous coil of wire material; the cold heading machine uses a series of powerful hammers and dies to form a part. This process creates very little to no waste, offers significant material cost savings, and the volume of the starting slug is about the same as the finished part. The net volume remains the same since the material is being formed into the die, rather than cut from the blank. The cold heading process creates a stronger part, with smooth continuous surfaces while enhancing the grain flow of the material.

In contrast, metal cutting operations are typically slow and can generate as much as 60% waste.

Cold heading is more efficient than machining, allowing rapid production of large quantities while maintaining tolerances as close as +/- .002″ without secondary operations.

Progression

A progression is the process of developing gradually towards a more advanced state. Starting with the slug, each step of the progression forms the material closer and closer to its’ final shape. Intricate fasteners often require a longer progression than simple fasteners, as many simple fasteners may be completed in 1-2 blows from a cold heading machine.

Progressions are not the same for every part. Each type of fastener or component has its’ very own series of punches, dies, and hammers which have been engineered to a unique specification. Material requirements also play a role in how the progression is designed. Softer metals will form more readily (e.g. Copper, Aluminum) while harder metals (e.g. Stainless Steel, Nickel Alloy) may require multiple blows to achieve its’ final form.

Basic Forming Techniques

Upsets and extrusions are two basic types of techniques used in cold headed manufacturing. These techniques involve the controlled forming of a material by applying enough force for the material to fill a voided space within a die. Each die is engineered accordingly, to produce the proper amount of material movement throughout the progression.

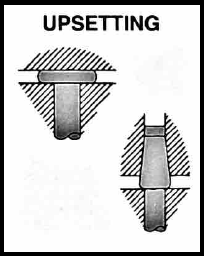

Upsets

Upsets are the most common and basic technique used in cold heading today. An upset is formed when the slug is reduced in height and the starting diameter is increased. This technique is often used to create the head of the part, and may be formed with open tooling, between tooling, or enclosed tooling – depending on the upset location and shape. Integral parts may require multiple heads and diameters. To achieve these complex configurations, different upsets are incorporated throughout the part’s progression.

Extrusions

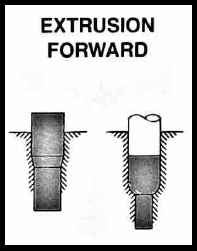

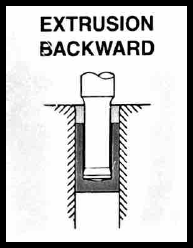

Another common cold heading technique is called an extrusion. There are two types of extrusions: forward extrusions, and backward extrusions.

Forward extrusions force the material through a smaller diameter orifice, thereby reducing its diameter and increasing its length. The starting material may be partially or totally contained in the tooling before the start of this type of extrusion.

Backward extrusions force material to flow around a penetrating punch or pin while being contained in a die or punch insert. This extrusion is typically used to form a hole or cavity inside a part.

Secondary Operations

Complex fasteners and components often require secondary operations to produce finished parts. These operations cannot be performed on a cold heading machine and are complimentary to the cold heading process.

-

Thread Roll

-

Drill and Tap

-

Knurling and Grooving

-

Stamping

-

Heat Treat

-

Plating

-

Grind and Shave

-

Metal Finishing & Polishing

-

CNC Milling

-

Flatten

-

Pierce